FIRE SUPPRESSION SYSTEM

|

Fire suppression systems are engineered and pre-engineered systems. An engineered fire suppression system works by flooding an entire room with clean agent. Clean agents are gases that suppress fires without harming humans or equipment. A commercial or industrial facility with critical electronic systems that would be severely damaged by a sprinkler system using water is a perfect fit for a clean agent engineered system. The goal of any fire suppression system is to detect fire as soon as it starts and immediately suppress it, preventing the fire from spreading.Heat and flames are detected, a trigger signals there is a fire, and the suppression system kicks into action suppressing the fire at the source. There are many types and sizes of fire suppression systems. The system design will vary based on the asset needing protection and the type of fire hazard. |

|

CLEAN AGENT FIRE SUPPRESSION SYSTEM VERY FAST STOPPING POWER FM -200 FM200 fire suppression is also known as HFC227ea. FM200 is a waterless fire protection system, it is discharged into the risk within 10 seconds and suppresses the fire immediately. There are many benefits to using a clean agent fire suppression system. These systems are fast, effective, safe, clean, and eco-friendly. |

|

INERT GAS FIRE SUPPRESSION SYSTEM

Inert gas suppression systems use argon and nitrogen gases and their mixtures as an extinguishing agent and are based in the principle of reducing the oxygen concentration inside the protected hazard. The oxygen concentration is minimized by the application of inert gas until it reaches a level where combustion is no longer supported. Each system is designed so as to decrease oxygen to a specific level. When discharged, inert gas is quickly and uniformly distributed within the enclosure, achieving design concentration in 60 seconds.

Argon and nitrogen it is naturally present in the atmosphere, therefore its green-house effect is nil and its ozone layer depletion potential is zero. It is chemically inert, non-conductive, colourless, odourless and flavourless. inert gas is non-corrosive and may be used at normal temperatures with such materials as nickel, steel, stainless steel, copper, brass, bronze and plastics.

CO2 FIRE SUPPRESSION SYSTEM

(1).jpg)

(1).jpg)

Fire suppression systems are designed to suppress or extinguish a fire in sensitive environments where water from a fire sprinkler is not a desired extinguishing agent. Common areas where you will find fire suppression systems include server rooms, engine rooms, flammable storage areas, museums, and data centers.

There are a few different types of agents that are used in a suppression system to suppress the fire. In server rooms and environments where you have personnel working in the area, you will usually find clean agent or inert gas suppression systems. In environments where there are few personnel or none at all, you will typically find CO2 fire suppression systems. The areas that you’ll find CO2 fire suppression systems include engine rooms, generator rooms, power stations, flammable liquid storage rooms, and around large industrial machines.

While CO2 fire suppression systems are highly effective at suppressing fires, the CO2 agent also poses a health risk when compared to the other agents. For this reason, you’ll find CO2 fire suppression systems most often in non-occupied environments.

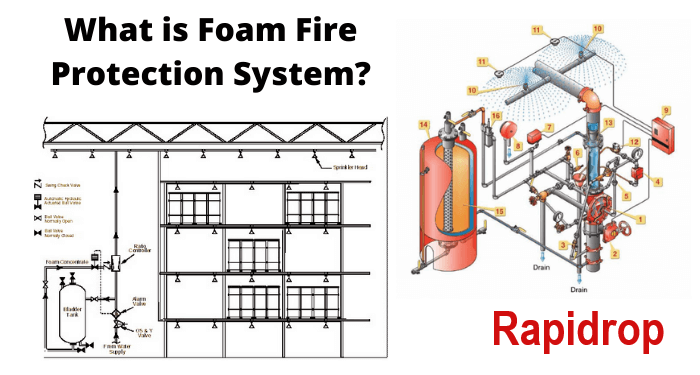

FOAM FIRE SUPPRESSION SYSTEM

A foam fire suppression system is a type of wet sprinkler system that combines both water and a foaming agent for large scale fire extinguishment.

This water-based fire sprinkler suppression system can extinguish extensive fires in mere seconds with incredible efficiency.

What is foam?

The “foam” in foam fire suppression systems is an extinguishing agent that can extinguish flammable or combustible liquid by cooling and separating the ignition source from the surface. The foam suppresses and smothers fire and vapors alike. It can also prevent reignition. It is also known as “firefighting foam.”

This foaming agent is made up of small air-filled bubbles that have a lower density than water. Foam is made up of water, foam concentrate, and air. Different manufacturers have their own foam solutions and concentrate. The proportion of foam to water depends on the application.

How do foam suppression systems put out fires?

Foam suppression systems extinguish fire by separating the fuel from the oxygen. In more technical terms, these systems are used to “cool the fire and coat the fuel that the fire is consuming to prevent contact with oxygen and reduce combustion ability.”

To do this, the extinguishing agent (the foam) smothers or blankets the surface of the fuel. The water content of the foam then cools the fuel and the area of foam covering the fuel to prevent reignition via flammable vapors.

How do foam suppression systems discharge?

Foam suppression systems are designed much like a wet sprinkler system in that stored water flows through a network of pipes where it is then discharged through nozzles. However, the main difference with foam systems and other traditional wet sprinkler systems is the addition of the foaming agent.

The foaming agent is stored separately from the water and the two are mixed within the piping system prior to discharge.

At the end of the piping is a nozzle. The foaming agent is added or ejected into the water at the very last moment before discharge. When the water mixes with the foaming agent, expansion occurs and creates an immense coverage of foam to fill expansive areas.

What are the common uses/applications for foam systems?

You’ll typically find foam suppression systems in large areas where there is a lot of flammable or combustible liquids. For example, some of the common uses include:

- Aircraft hangars

- Warehouses

- Marine applications

- Processing areas

- Flammable liquid storage

- Jet engine testing facilities

The reason that this type of system is most commonly used in these applications is because of the widespread capabilities of foam to not only extinguish but also smother flames in a way that prevents reignition.

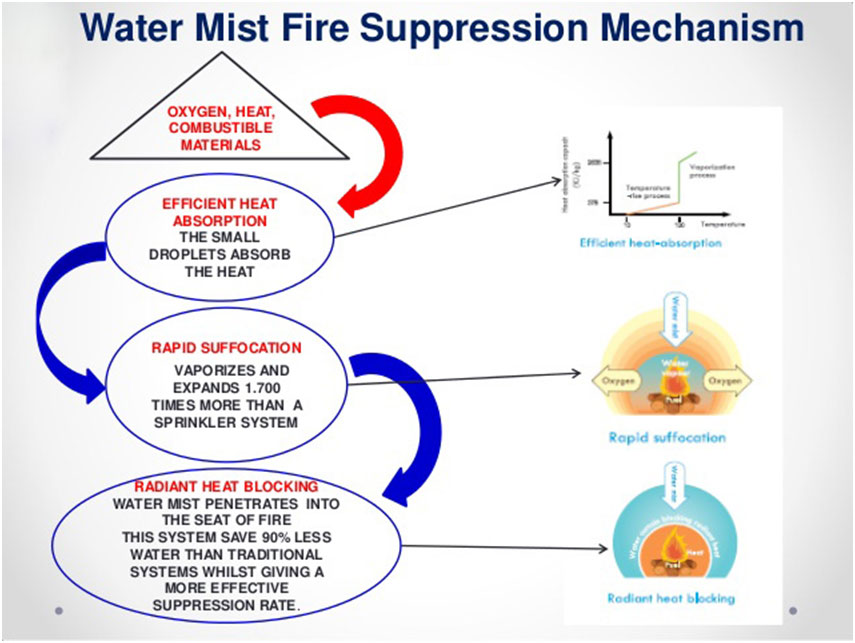

WATER MIST FIRE SUPPRESSION SYSTEM

Right Solution to Match the Risk

Water mist systems are a versatile and highly efficient fire protection solution, featuring unique nozzles that have been designed and rigorously tested to help protect against a wide range of fire risks. The fine mist the system generates can extinguish fire or limit its growth at an early stage, depending on the asset being protected. Water mist systems help provide effective cooling and fire control on Class A fires, or assistance with extinguishing and preventing re-ignition on Class B or Class F fires.

Comprehensive

A broad range of systems offering solutions to meet your needs.

Highly Efficient

Reduces water usage while providing superior control.

Tested and Approved

Designed and rigorously tested to protect against a range of risks.

A water mist system is a fire protection system which uses very fine water sprays (i.e. water mist). The small water droplets allow the water mist to control, suppress or extinguish fires by: cooling both the flame and surrounding gases by evaporation. displacing oxygen by evaporation.

KITCHEN HOOD FIRE SUPPRESSION SYSTEM

(1).jpg)

.jpg)

A kitchen hood suppression system releases wet chemical extinguishing agents designed to put out cooking fires. These chemicals react with grease to create a harmless soapy substance that can't re-ignite. This process, called saponification, protects the hoods, appliances, and plenum areas from the ravages of fire.

PRE – ACTION FIRE SUPPRESSION SYSTEM

Pre-action fire suppression systems are specialized sprinkler systems often found in museums, libraries, archives, refrigerated areas, computer rooms, data centers, and other sensitive areas where activation of a traditional wet pipe sprinkler system could result in water damage to valuable artifacts, sensitive ...

DELUGE FIRE SUPPRESSION SYSTEM

A deluge fire protection system has unpressurized dry piping and open sprinkler heads. The system is directly connected to a water supply and when the system is activated, a deluge valve will release the water to all the open sprinkler heads. The valve is opened when activated by a heat or smoke detection syste

Numerous fire suppression options on the market, it’s often a challenge to determine which type of fire suppression systems is ideal for your facility, its critical assets, and most importantly, its occupant’s main focus is on development projects to supply, maintenance and install, automatic fire-suppression systems. Wasib solutions offers products and solutions with the best price-to-quality.

Fire Fighting Foam Monitor Systems

Foam monitors high flow rates and pressures, foam monitors with long throw distances play an important role in fire extinguishing, especially in tank areas or where combustible flammable liquids are stored.

Foam monitors capable of manual intervention in fire-fighting areas, WSL Fire Safety Systems. imported from abroad by. All imported foam monitors have internationally recognized approvals such as FM, UL, VdS, GOST, LPCB and are first class materials.

The supplied foam monitors provide remote control capability, as well as manual control, Depending on the project requirements, the monitors can have 360 degree horizontal rotation and 90 degree vertical rotation, taking into consideration the area.Which can interfere with the fire. With this feature, it is possible to interfere with a protected area maximize safety.

The platforms that make it possible to use most monitors with monitors are manufactured by Rapidrop Global Ltd.

The outlet pressures and adequacy of foam monitors and their appropriate ejection distances - heights; Rapidrop are determined by the engineering department at the optimal level in accordance with the needs and East African fire safety solutions are realized.